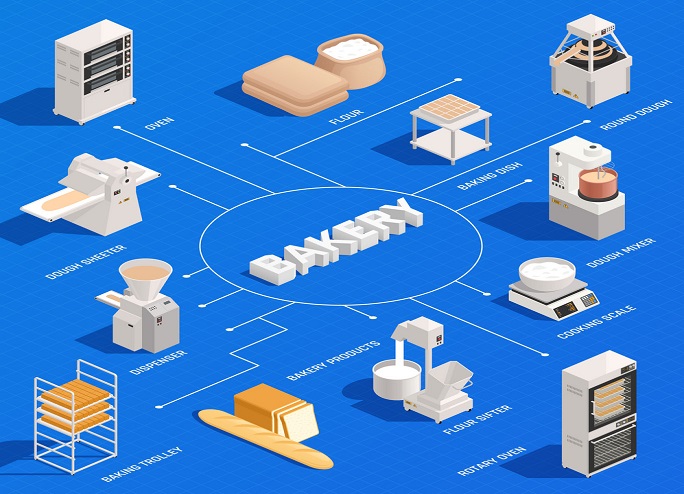

Turnkey Solutions

We have a unique blend of knowledge, experience and partner companies to offer turnkey solutions for Biscuit Manufacturing. We can offer an optimised solution for dough mixing, dosing solution, process of fermentation, shaping, baking oven and finally packaging.

We have a group of companies holding more than 15000 sq. ft. and 200 professionals and technicians to support fabrication and manufacturing requirements, a moulding and machine manufacturing unit with 150 employees focused to cater machinery needs and another unit with more than 200 tech professionals to develop and install enterprise resource planning and digital infrastructures. RTM will be providing project management, design, shop floor integration, automation, robotisation and commissioning and startup support to deliver the nameplate facility we develop for a production unit.

Consulting for Digital Manufacturing

With more than 100+ years of combined knowledge of manufacturing, machining, fabrication, assembly, industrial robotics, mobile robotics, serial and batch production within the team members, the team at RTM has an in-depth understanding of the entire spectrum of the manufacturing.

Team RTM with their vast experience, offers partial and complete transformation of existing manufacturing set up into fully digital and connected manufacturing.

Solutions range from digitising the systems, automating the systems, capturing Key Performance Indicators, displaying relevant dashboards to stakeholders, implementing artificial intelligence to predict loss of productivity, predict the need for maintenance & raising anomalies in the entire system.

Data capture and Analysis

With combined knowledge of Production, Manufacturing and Implementation of various F&B or FMCG applications Robo Tech Mech Solutions Ltd. is capable of bringing your plant floor to your fingertips. RTM can review the production unit and identify the need for data points, advise and set-up the data capture system for all current and historical data. Various data flows are validated and in the end data analysis is performed to be displayed on a single dashboard for complete monitoring of your production unit on your finger tips.

Using asset analytics various KPIs can be developed, for the production unit Production Totalizer, Total Dispatch, Asset Energy Consumption, End of the total mass of gross final products per mass of gross of raw material input in your production units.

Production Execution System will enable you to connect Information Technology (IT) and Operations Technology (OT) users to access the same data to develop multiple user or department level dashboards. This mainly covers the Total Production, Energy Consumption, Material INput Utilised, Number of Laboratory Interactions, Equipment Stop of down time.

Production Supply Chain Management

With more than 100+ years of combined knowledge of manufacturing, machining, fabrication, assembly, industrial robotics, mobile robotics, serial and batch production within the team members, the team at RTM has an in depth understanding of the entire spectrum of the production, supply and its management.

Team RTM with their vast experience, offers partial and complete transformation of existing manufacturing set up into fully digital and connected production systems.

Solutions range from digitising the systems, automating the systems, capturing Key Performance Indicators, displaying relevant dashboards to stakeholders, implementing artificial intelligence to predict loss of productivity, predict the need for maintenance & raising anomalies in the entire system.

Integrated Solution, Connected Plant

RTM specialises in creating solutions for F&B industry. The plant or factory owners face steep challenges when there has to be a step change for improvement in quality or to gather business relevant data from the factory floor. RTM team works with the stakeholders to understand pain points when quality improvement is the target. RTM devises the required sensors and systems along with the accompanying software for gathering plant health and quality. This helps the owners in measuring the vital parameters of production and take decisive actions.

RTM uses the latest technology to build Industry 4.0 ready connected plants. The main strength of RTM is in building shop floor level automation systems as well as connecting those to edge hardware and enterprise software.

Training

Courses are offered in two main areas. Production Unit Digitization and for Production Unit Robotization. All courses are customisable to meet the audience or trainee requirements.

Production Unit Digitization courses are targeted for the production unit management team. These training courses will deep dive into today’s disruptive technologies and will enable you with the knowledge to select the best technology for your production unit, how to calculate return on your investment and how to investigate implementation for the same.

Production Unit Robotization courses are targeted for the production unit’s technically involved team or team involved in the day to day operation. These courses will enable your technology team with robotization knowledge to accelerate production rate, course also focus on other operation and maintenance issues involved with Robotization of the production unit.